Introduction

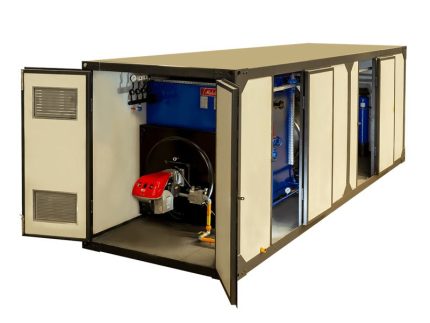

Our electric steam boilers operate with approximately %95-%99 efficiency at all loads and variable loads do not affect boiler efficiency. In order to reach the desired pressure and temperature, the heating elements are activated and deactivated with a gradual control system. All heating elements on the boiler can be replaced independently of each other, without the need for any welding or soldering. Surface heating loads are kept to a minimum in order for the heating elements to have a long life.

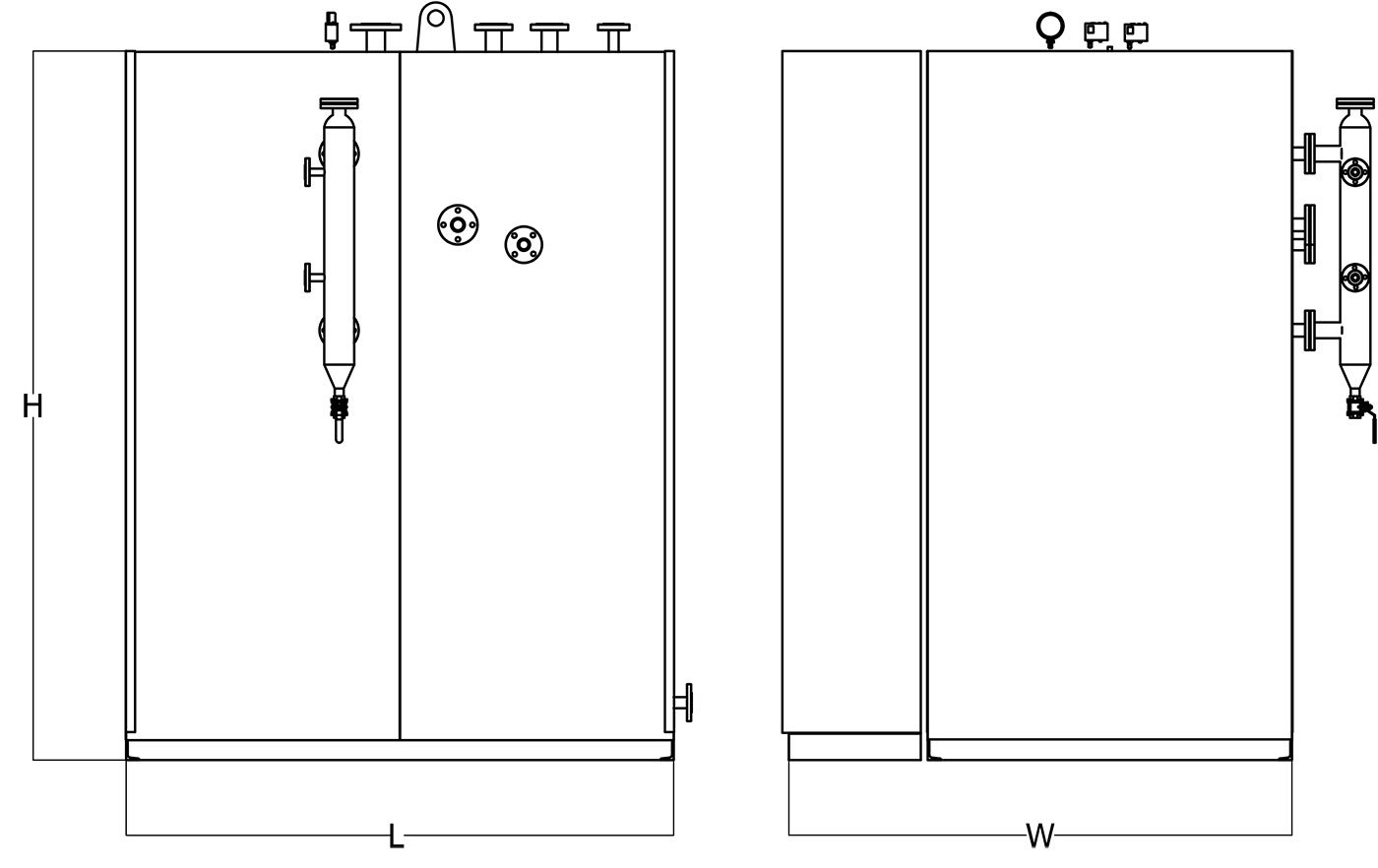

The perfect boiler design is designed so that water circulation occurs in the most appropriate way around the heating elements and heat transfer is maximum. Water velocities are selected to cause minimum pressure losses, and the inlet and outlet ports are placed in a diameter and position that will provide optimum flow conditions. High capacity CPU and 7” touch screen usage provides unique process monitoring and ease of use.

With 15 kW resistances used in the design, the boiler capacity can be adjusted to the desired power and its use can provide the desired power.

Application Areas

Domestic and Industrial areas

Food (Milk, Cheese, Meat, Ready-made foods, Beverages)

Autoclave

Textile, Laundry, Dry cleaning

Hotel, Hospital Public areas.

Plastic, Rubber

Heating and Domestic hot water

Tourism sector

Pharmaceuticals

Evaluate your investments such as GES and RES with Our EBK series boilers. Since the contribution share of renewable energy in the electricity grid increases, electricity obtained from wind and solar energy in particular can be evaluated in this way. BENEFIT FROM THE ECONOMIC USE OF THE EXCESS ELECTRICITY YOU PRODUCE