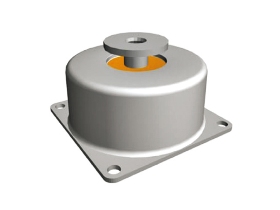

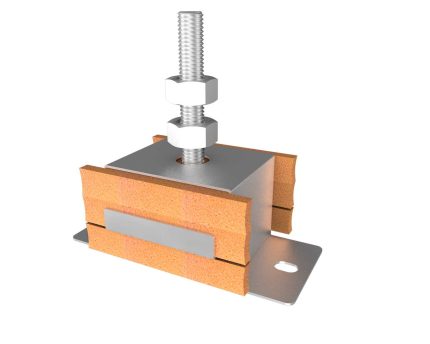

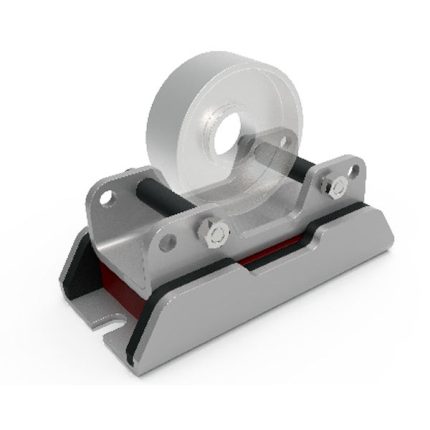

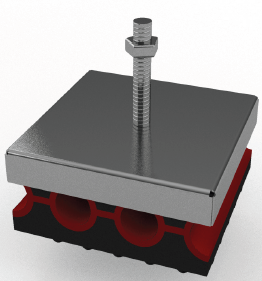

The galvanized metallic shell of Vibro-3D protects the internal elastic parts from corrosive environments and therefore ensures longevity even in very hard and corrosive conditions. Additionally Vibro-3D meets high safety standards due to its unique design that even in case of exposure in destructive conditions (Fire) that will destroy the internal elastic parts, its top fixing, that holds the suspended device does not fail (Fail Safe).

Vibro-3D covers a wide range of loads, due to its capability to change the density and stiffness of the internal polyurethane foams, it also has the ability of angular misalignment of up to 150.

It is available with Female ending (type F), male (type Μ), and with special top female fixing for mounting (type SF).

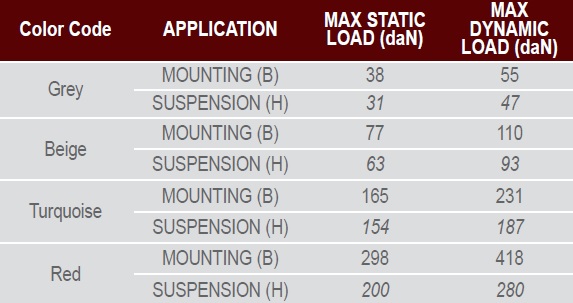

Vibro-3D can be used either for mounting or for suspension of respectively loads.

Note: The maximum load for the radial force shall be 15% of the mounting load.