WRONG VENTILATION SYSTEM DESIGN

– WHAT ARE THE EFFECTS?

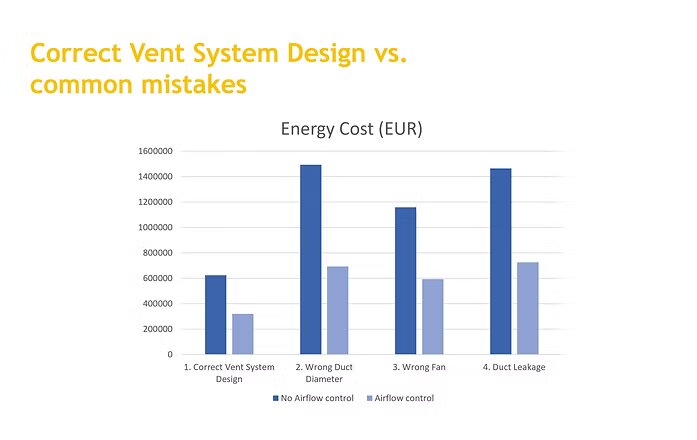

1. WRONG CHOICE OF AIR FLOW

Too low airflow leads to longer time to ventilate the blasting fumes which leads to slower tunneling speed. If the airflow is higher than required, this leads to higher investment costs of fans and higher running costs.

2. WRONG DUCT DIAMETER

The duct diameter determine the air flow velocity and the pressure inside the duct. The duct pressure determines the number of fans and/or kW rating of the fans, and the power load of the fans. The power load is directly proportional to the power costs to run the fans.

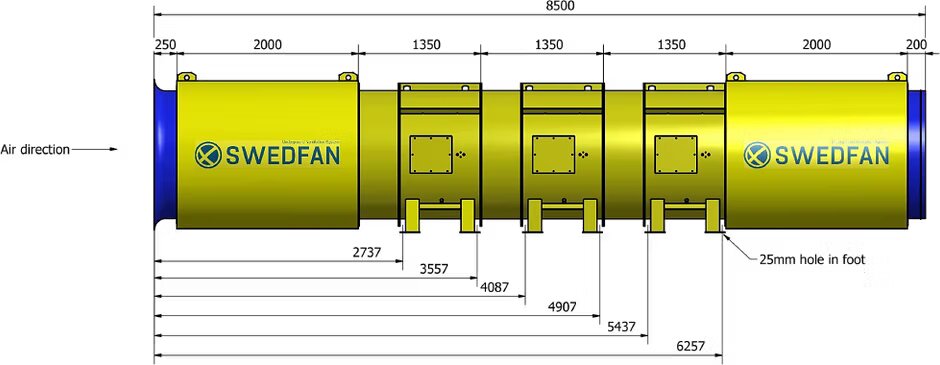

3. WRONG FAN

The fan should be chosen to meet the capacity according to the calculated duct pressure and airflow. Too low airflow means no efficient tunneling which results in lower profit for the project. Too high airflow cause higher duct pressure which increase the energy costs.

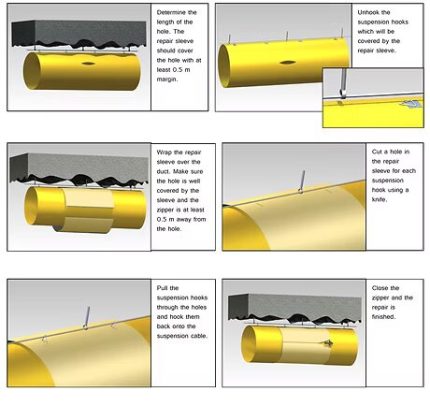

4. DUCT LEAKAGE

When calculating the required airflow delivered by the portal fan station in relation to the required airflow delivered to the tunneling front, a duct leakage must always be assumed. The leakage depends on how well the joints of each duct section are designed, the duct quality and how well damages are repaired.

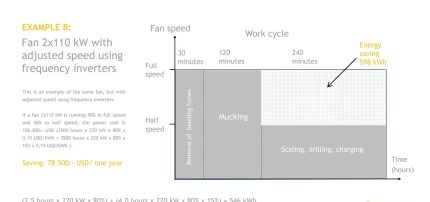

5. NO AIRFLOW CONTROL

Normally, max airflow is required when ventilating the fumes after blasting and when mucking is executed. A reduced airflow can normally be accepted during works such as drilling, scaling, charging. With frequency inverters, a great energy cost saving is possible if the fan speed/airflow is controlled and regulated depending on what tunneling works are carried out.