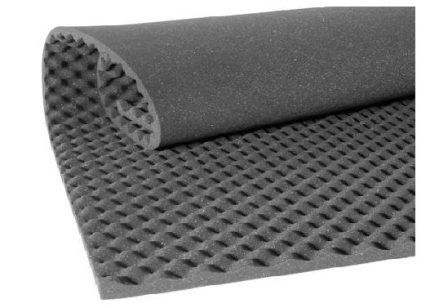

ISOLFON-ReΒond is produced from recycled flexible polyurethane foams pressed & bonded with polyurethane glue and it is designed to offer sound Absorption, soundproofing & impact vibration isolation.

It’s primary application is to solve complex acoustic problems in buildings.

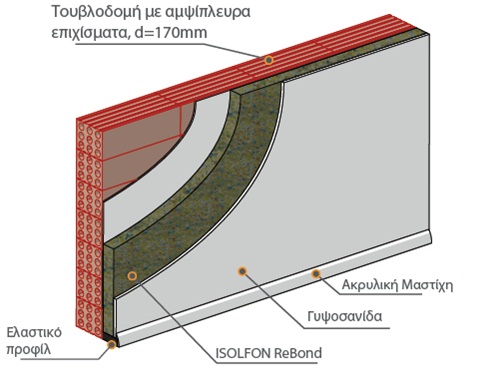

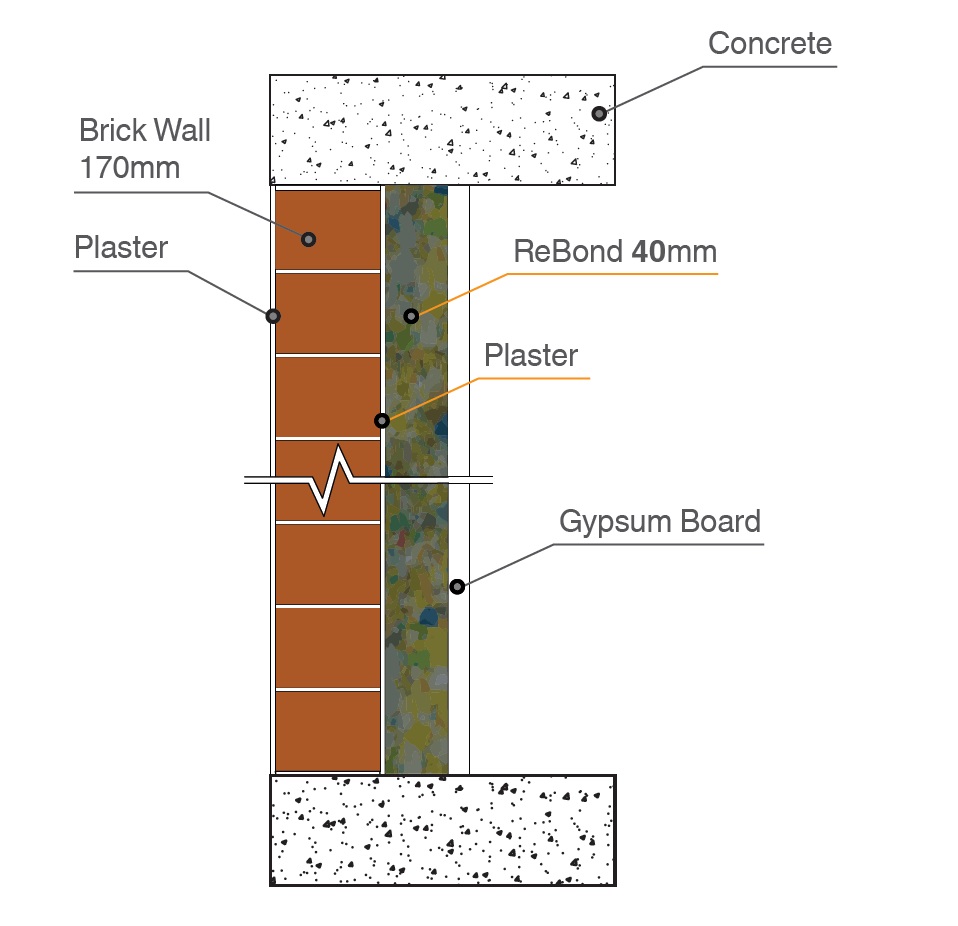

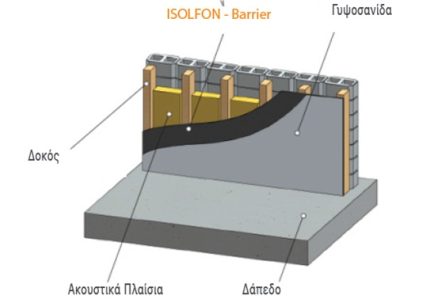

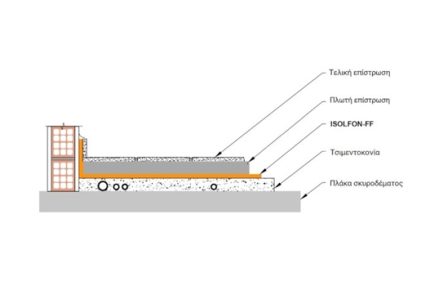

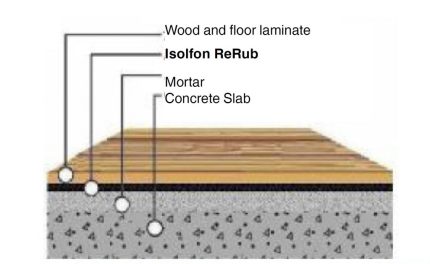

Used in wall & ceiling cladding, to fill the air gaps and create the Mass Spring effect, to improve the Sound Insulation properties of the wall system. The consistency and elasticity of ISOLFON-ReΒond composition, is used as «spring», in combination with materials which play the role of the mass (plasterboards, MDF, hardboard etc.). The result of such a composition is unparalleled Impact Vibration Isolation.

Soundproofing

The noise reduction of a single-layer partition, is depended by their surface mass, -deflection- stiffness. As doubling the mass, increases sound

insulation by 6 dB. To ensure good noise reduction (Rw ≤ 50 dB), single layer partitions require a surface masses of greater than 250 kg/m².

For multi-layer panels with facing, greater noise reduction can be achieved with less mass, taking advantage of the mass-spring principle.

Sound Insulation can be improved by, increasing the gaps between layers. To avoid cavity resonance, the gap should be filled with soundabsorbing

light weight soft material, such as ISOLFON-ReBond.

Sound Reduction index Rw(dB) according to ISO 10140 & ISO 717.1